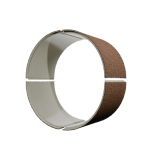

Standard liner

Understanding glass reinforced plastic and its role in infrastructure rehabilitation

Glass reinforced plastic (GRP), also known as fiberglass, is a highly versatile and durable material that plays a crucial role in modern infrastructure rehabilitation. GRP is made from extremely fine strands of glass called fibers and a polymer resin, creating a composite material that offers exceptional strength while remaining lightweight.

GRP and its versatility in infrastructure rehabilitation

In the field of infrastructure, GRP has become a go-to material for rehabilitating critical systems, particularly aging pipelines, culverts, and tunnels that carry wastewater, stormwater, and other essential services. Traditional materials like concrete and steel, while sturdy, are prone to corrosion, chemical damage, and degradation over time. GRP, on the other hand, provides superior resistance to these issues, helping to extend the life of aging infrastructure without the need for complete replacement.

Key benefits of GRP in infrastructure:

-

Corrosion resistance: GRP does not corrode like steel or concrete, making it ideal for environments exposed to harsh chemicals, water, and other corrosive or abrasive substances.

-

Lightweight yet strong: Despite being much lighter than traditional materials, GRP offers incredible strength, enabling easier installation without compromising durability.

-

Longevity: With resistance to extreme temperatures, UV radiation, and chemical exposure, GRP can last for decades with minimal maintenance, often outlasting the materials it replaces.

-

Customizability: GRP can be molded into different shapes and sizes, making it a fantastic solution for rehabilitating structures of all shapes and sizes.

Because of these qualities, GRP is frequently used to rehabilitate failing infrastructure rather than replacing it entirely. This method is both cost-effective and less disruptive, as it allows municipalities and industrial sectors to extend the life of their systems without the extensive downtime and expense associated with full-scale replacements.

How Channeline’s GRP liners are different

While GRP is widely used in infrastructure rehabilitation, not all GRP products are created equal. At Channeline, we have developed a GRP liner that offers distinct advantages over standard GRP solutions.

Standard GRP pipework consists of windings of layers of resin-saturated glass, to which sand is added. Strength and stiffness in these products is achieved by increasing the thickness of the pipe wall. While effective, this approach can limit the internal diameter of the pipe, reducing flow capacity and requiring more material to meet strength demands.

Channeline’s GRP innovation

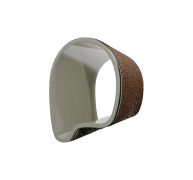

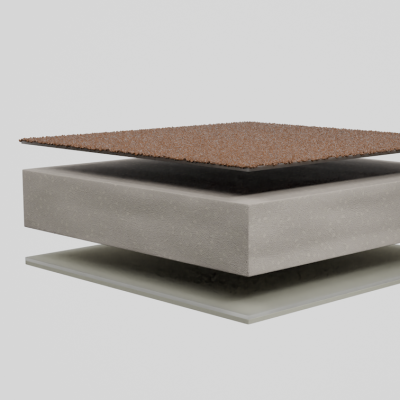

Instead of simply increasing wall thickness to gain strength, Channeline uses a patented sandwich panel design in our GRP liners. This design incorporates a unique polymer and aggregate core. The result is a liner that achieves high strength and stiffness with a much thinner wall. This innovative design allows for maximum cross-sectional area inside the pipe, optimizing flow rates while maintaining the structural integrity required for long-term performance.

Our liners are designed to meet the demanding conditions of infrastructure rehabilitation, offering:

-

Thinner walls with superior strength: Our sandwich panel design allows for thinner GRP walls without sacrificing strength, meaning larger internal diameters for improved flow.

-

Longevity: Channeline liners are designed to last, with a service life of 150 years, providing a cost-effective, long-lasting solution for aging infrastructure.

-

Any shape, any size: Channeline’s GRP liners are custom designed and manufactured, meaning they meet the specific needs of each project, ensuring optimal performance and longevity. Plus, Channeline’s unique technology means that large diameter projects can be catered for using multisegmental liners, with no sacrifice to the strength or lifespan of the solution.

-

Better installation options: Thanks to Channeline’s bespoke service, liner panels can be created to offer cost-saving installation benefits from nested transportation to installation in live flow.

-

Sustainable solution: With a lower carbon footprint than traditional infrastructure materials, GRP liners offer a sustainable solution for the world’s infrastructure needs.

In summary, GRP is a highly effective material for infrastructure rehabilitation, offering numerous advantages in terms of strength, resistance, and durability. At Channeline, we take GRP technology to the next level with our innovative fully-structural lining systems, ensuring that our solutions not only restore aging infrastructure but also enhance performance and offer better installation options.