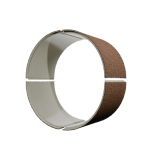

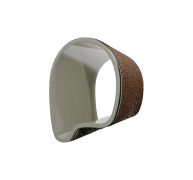

Standard liner

Cooling

infrastructure

There are many design considerations to take into account within a seawater cooling network, with water pumped from a lake or ocean, then moved through a heat exchanger, before being circulated around pipes to cool buildings.

Usually these systems use steel pipes and replacement is very expensive.

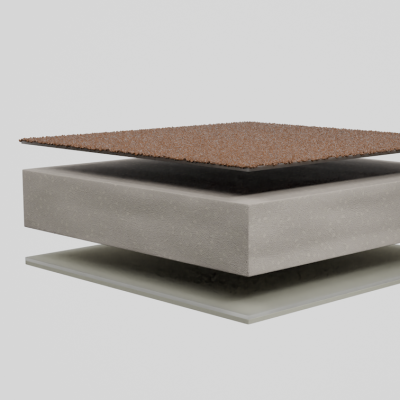

Channeline offers a cost-effective alternative to replacement, instead rehabilitating the existing structure using our fully-structural liners. Thanks to our custom design and manufacturing processes, we can take all of the design considerations into account to produce a fully-structural rehabilitation solution tailor-made to the existing structure.

How we work

Project evaluation

Our expert team take care to understand the requirements and nuances of each project. This usually involves surveying the host pipe, which we can help arrange, and a site visit.

Bespoke design service

Our in-house design team creates a custom design to fully satisfy project requirements and specifications. If required, the design can be validated using finite element analysis.

Manufacture, with quality in mind

The bespoke manufacture of product begins. Quality control is undertaken both during and on completion of the manufacturing process. If required, third party inspection and validation can be arranged.

Dedicated logistics support

The finished solution is prepared for shipping and dispatched to the project location. Our dedicated logistics team and client liaison provide end-to-end support until the arrival of goods.

Installation supervision

Training and support for installation can be provided by our team on request.