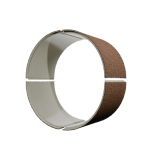

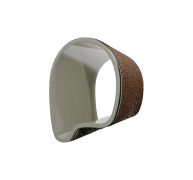

Standard liner

Revolutionizing

sanitation

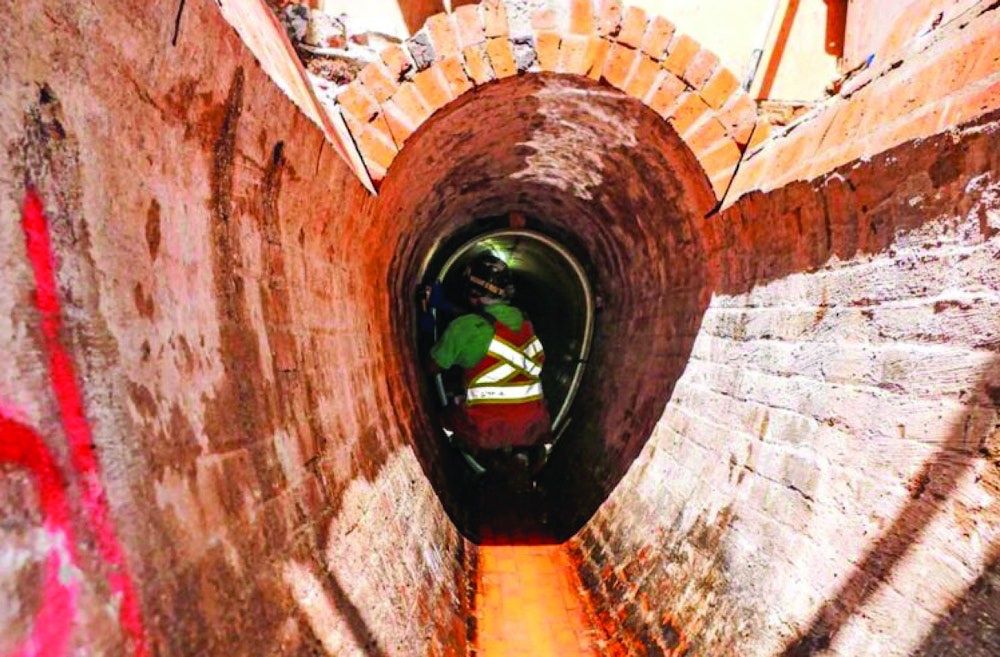

Buried, large-diameter pipelines and culverts have represented the backbone of any city’s utility network, in some cases for hundreds of years, but many of these are failing due to age. Wastewater systems commonly have very low pH values and a build up of sulfuric acid that gradually corrodes brick, stone, concrete and steel pipes until they finally lose their integrity completely.

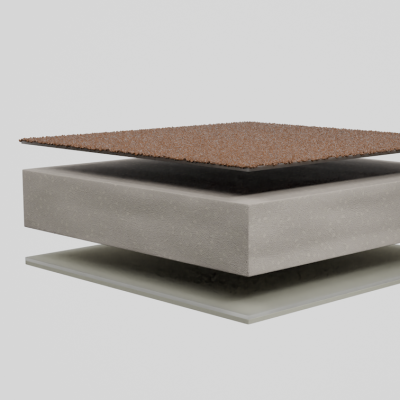

Channeline uses glass reinforced plastic - also known as fiber glass or GRP - to produce fully-structural rehabilitation solutions. Known for its low-weight, high-strength qualities, GRP is also highly resistant to corrosion, making it able to easily withstand the low pH values found in wastewater systems. Channeline GRP products have been shown through rigorous testing to offer a service life of 150 years.

The smooth lining of our products has also been shown to increase hydraulic capacity by up to 25%. Additional coatings can also be applied to ensure top performance and durability even in the most challenging conditions, for example industrial applications.

How we work

Project evaluation

Our expert team take care to understand the requirements and nuances of each project. This usually involves surveying the host pipe, which we can help arrange, and a site visit.

Bespoke design service

Our in-house design team creates a custom design to fully satisfy project requirements and specifications. If required, the design can be validated using finite element analysis.

Manufacture, with quality in mind

The bespoke manufacture of product begins. Quality control is undertaken both during and on completion of the manufacturing process. If required, third party inspection and validation can be arranged.

Dedicated logistics support

The finished solution is prepared for shipping and dispatched to the project location. Our dedicated logistics team and client liaison provide end-to-end support until the arrival of goods.

Installation supervision

Training and support for installation can be provided by our team on request.