Standard liner

Product

overview

Many pipelines and sewers are constructed with incoming lateral connections throughout the length of the structure. The rehabilitation of these is easy and straightforward with Channeline.

Laterals can be connected with mesh and mortar where necessary. For severely degraded lateral connections, repair mortars and GRP inserts can be prefabricated, installed and subsequently bonded to the main sewer liner to provide a smooth, durable solution.

Further, thanks to our custom design and manufacturing processes, Channeline can design and fabricate any desired fittings including:

- Concentric reducers

- Eccentric reducers

- Dished ends

- Y pieces

- Reducing tees

Why

Channeline?

Unrivaled experience

Channeline has over four decades of experience specialized in the design and manufacture of circular and non-circular buried infrastructure for our clients worldwide.

150 year service life

Longevity is important to us, and a key part of our vision. Our products have been proven via independent testing (using the long-term creep retention test) to have a service life of at least 150 years.

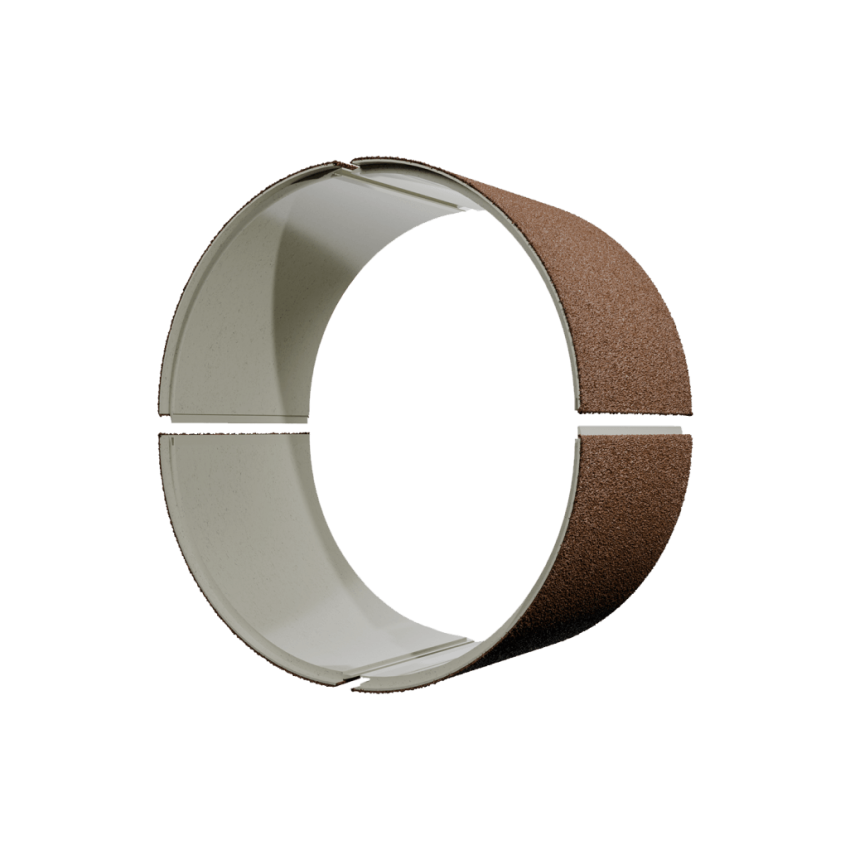

Any shape, any size

Our completely bespoke design and manufacturing capabilities mean we can provide fully-structural liner products at any shape, and any size. We also offer multi-segmental products that are perfect for large-diameter projects or more complex logistical needs.

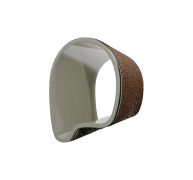

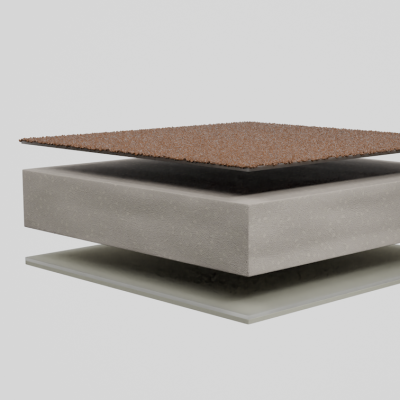

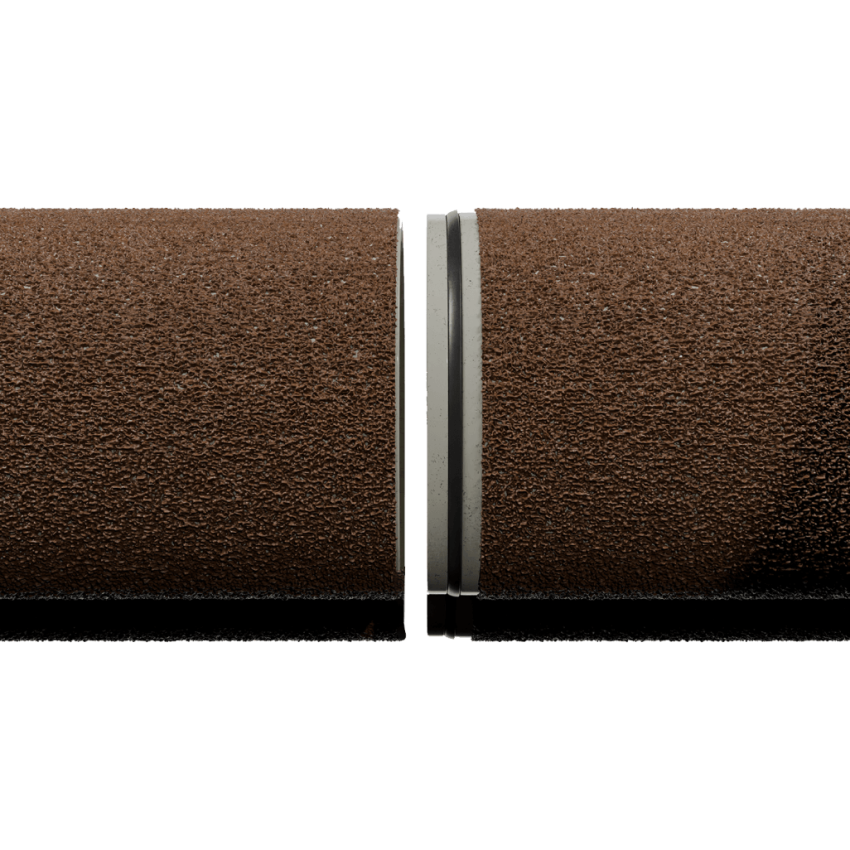

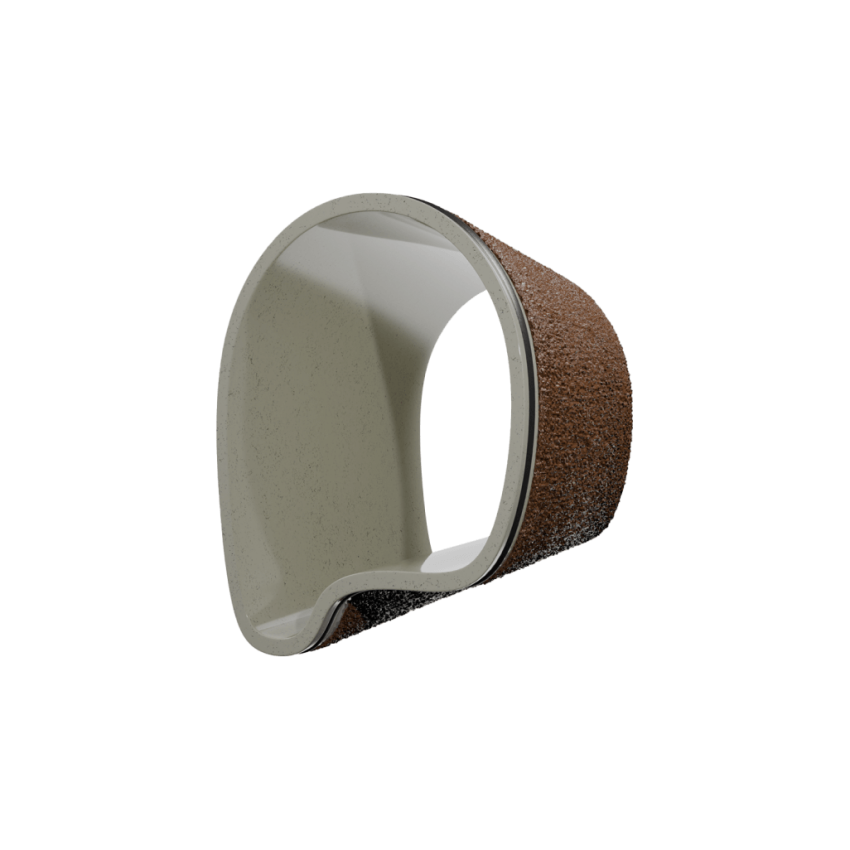

Thinner than standard GRP

Our patented technology uses a sandwich panel method combining a unique polymer and aggregate core. This means that our product is remarkably stiff and strong, but with a relatively thin wall. This is important as we maintain as much cross-sectional area as possible.

How we work

Project evaluation

Our expert team take care to understand the requirements and nuances of each project. This usually involves surveying the host pipe, which we can help arrange, and a site visit.

Bespoke design service

Our in-house design team creates a custom design to fully satisfy project requirements and specifications. If required, the design can be validated using finite element analysis.

Manufacture, with quality in mind

The bespoke manufacture of product begins. Quality control is undertaken both during and on completion of the manufacturing process. If required, third party inspection and validation can be arranged.

Dedicated logistics support

The finished solution is prepared for shipping and dispatched to the project location. Our dedicated logistics team and client liaison provide end-to-end support until the arrival of goods.

Installation supervision

Training and support for installation can be provided by our team on request.

Industries

Applications

01

Wastewater

Buried, large-diameter pipelines and culverts have represented the backbone of any city’s utility network, in some cases for hundreds of years, but many of these are failing due to age. Channeline's fully-structural rehabilitation solutions give a new life to existing structures.

02

Stormwater

Heavy rainfall and impervious surfaces such as roofs and asphalt roads leading rain directly into sewer systems often cause sewers and wastewater treatment plants to reach their full capacity. An effective and reliable network of stormwater drainage infrastructure is needed to combat this challenge. Channeline offers a fully-structural rehabilitation solution for stormwater drainage systems.

03

Seawater cooling networks

Usually seawater cooling systems use steel pipes and replacement is very expensive. Channeline offers a cost-effective alternative to replacement, instead rehabilitating the existing structure using our fully-structural liners.

04

Tunnels

Channeline’s capability to manufacture large-diameter, multi-segmental products enables the fully-structural rehabilitation of tunnels of any size.

05

Custom

Channeline excels in crafting bespoke solutions tailored to meet diverse client needs. Leveraging cutting-edge technology and extensive expertise, we meticulously design and manufacture custom products for various applications.