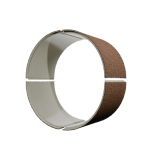

Standard liner

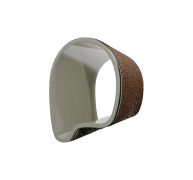

A unique solution

The general concept of the Channeline product is that a remarkably stiff and strong panel section is constructed, but with a relatively thin wall. This, combined with our unique finish, makes the product perfect for the rehabilitation of buried structures, maximising possible cross-sectional area and improving hydraulic flow.

Plus, with a service life of 150 years, Channeline offers a long-lasting and environmentally friendly solution to buried infrastructure rehabilitation.

How is our GRP different?

Glass reinforced plastic - also known as GRP or fiber glass - is an incredibly versatile material. It has low weight yet high strength, as well as resistance to chemicals, corrosion, UV and extreme temperatures, making it an excellent choice for pipework and lining systems.

Our product differs from standard GRP hand or filament wound pipework in several fundamental and important ways. Standard GRP pipework consists of windings of layers of resin-saturated glass, which is impregnated with sand, achieving its stiffness by building up ever-increasing wall thickness.

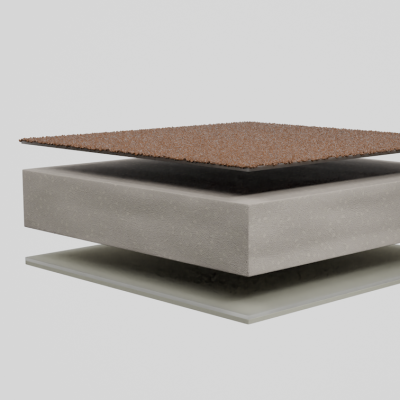

Channeline derives its strength and stiffness through a different method, employing the mechanics of sandwich panel design, incorporating a unique polymer and aggregate core. This patented technology means that our product is thinner than standard GRP, maximizing possible cross-sectional area, while still achieving the strength required, and a 150-year service life.

Design specifications

WIS 4-34-02

The most commonly-used design is the WIS 4-34-02 specification for GRP Sewer Lining in accordance with the Water Research Centre Sewerage Rehabilitation Manual.

BS5480

The specification for glass reinforced plastics (GRP) pipes, joints and fittings for use for water supply or sewerage.

ASTM D3262

The standard specification for fibreglass (glass-fiber-reinforced thermosetting-resin) sewer pipe.

MOP 145 specification

Design of close-fit liners for the rehabilitation of gravity pipes.

AWWA M45 specification

Manual of water supply practices - M45 fiberglass pipe design

ATV-M-127-2

The German Code ATV-M 127-2, published in 2000, for the design of linings to rehabilitate sewers.

Other

Where the above design methods are not acceptable, Channeline can design utilising finite element analysis.

Why

Channeline?

Unrivaled experience

Channeline has over four decades of experience specialized in the design and manufacture of circular and non-circular buried infrastructure for our clients worldwide.

150 year service life

Longevity is important to us, and a key part of our vision. Our products have been proven via independent testing (using the long-term creep retention test) to have a service life of at least 150 years.

Any shape, any size

Our completely bespoke design and manufacturing capabilities mean we can provide fully-structural liner products at any shape, and any size. We also offer multi-segmental products that are perfect for large-diameter projects or more complex logistical needs.

Thinner than standard GRP

Our patented technology uses a sandwich panel method combining a unique polymer and aggregate core. This means that our product is remarkably stiff and strong, but with a relatively thin wall. This is important as we maintain as much cross-sectional area as possible.

Quality assurance

At Channeline, our quality philosophy is simple: to produce the best GRP rehabilitation liners in the world. This means not only ensuring the quality of each and every liner that we produce, but also to continually strive to further enhance the quality and performance of our products. This is a continuous process which actively integrates everyone involved in manufacture, from senior management through to our people on the factory floor.

Learn moreCertificates and accreditations

BENOR

2024