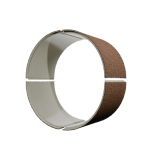

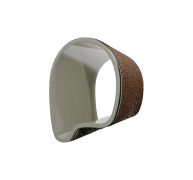

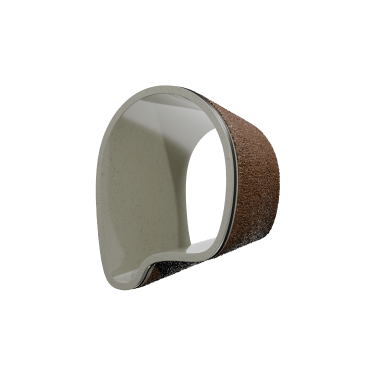

Standard liner

Product

overview

Channeline products are all custom designed and manufactured to meet our client’s needs. This means we can produce any of our products at any size and shape, and combine a number of products into one solution. We also offer a number of additional product enhancements, such as:

- Anti-slip grit: Aid safe installation with anti-slip grit on the liner invert.

- Precision grout ports: Strategically placed ports for grouting annular gaps can be added during design and manufacture, removing the need to add these later.

- Mounted centralizing skids: Simplify installation and ensure the correct positioning of liners, as well as ensuring optimal grouting.

- GRP rail mounting system: Ease the installation of crown-only solutions, with a rail installation system.

- Convenient hoisting points: Enhance installation ease with strategically placed hoisting points.

- Ecological enhancements: Safeguard wildlife within and around the system with product enhancements like fish baffles and animal walkways.

No challenge is too great for our team of experts. With our commitment to innovation, and our custom approach, we can accommodate a multitude of requirements and tailor a solution to your unique needs. Simply provide us with the problem, and

we’ll deliver the perfect solution.

Why

Channeline?

Unrivaled experience

Channeline has over four decades of experience specialized in the design and manufacture of circular and non-circular buried infrastructure for our clients worldwide.

150 year service life

Longevity is important to us, and a key part of our vision. Our products have been proven via independent testing (using the long-term creep retention test) to have a service life of at least 150 years.

Any shape, any size

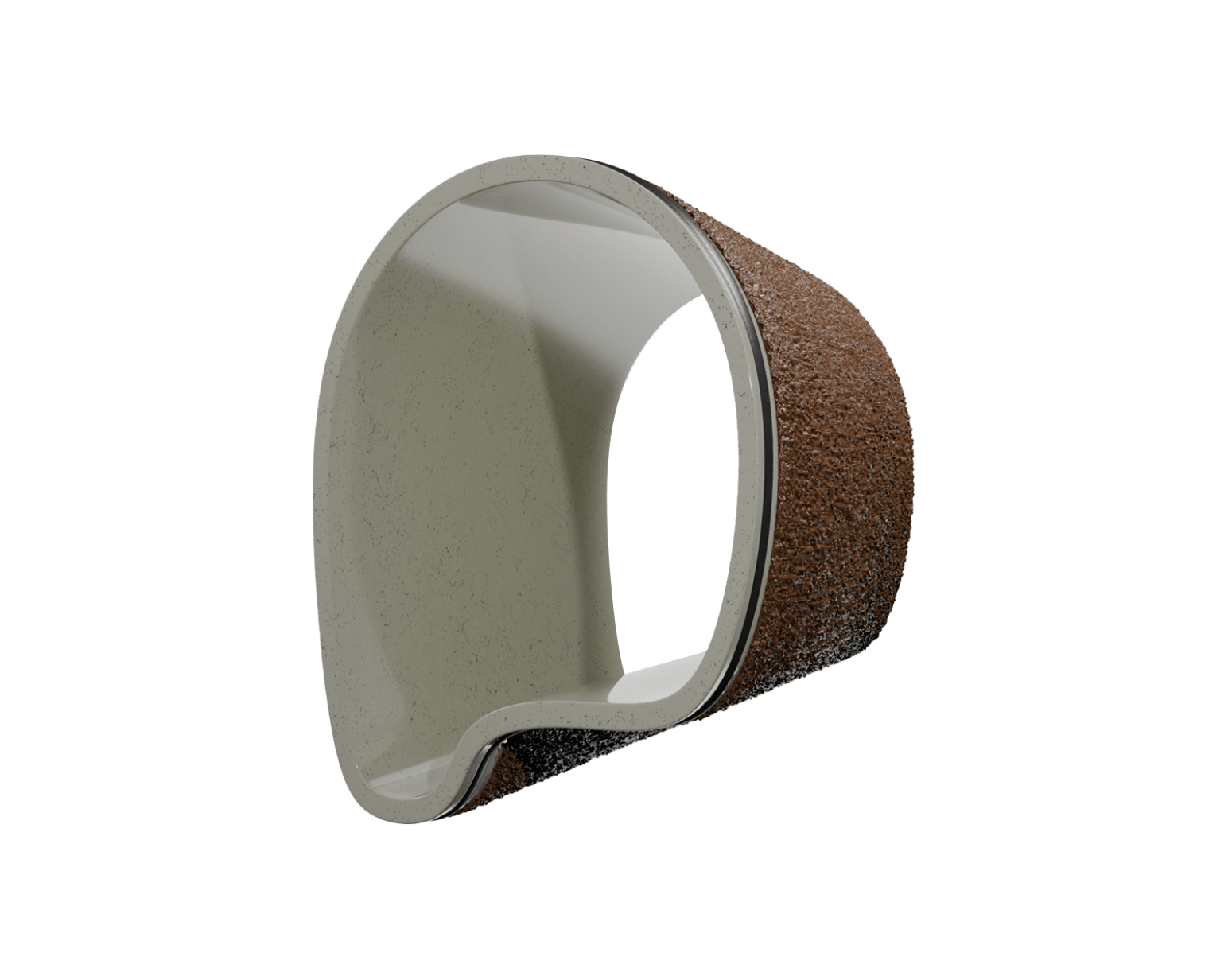

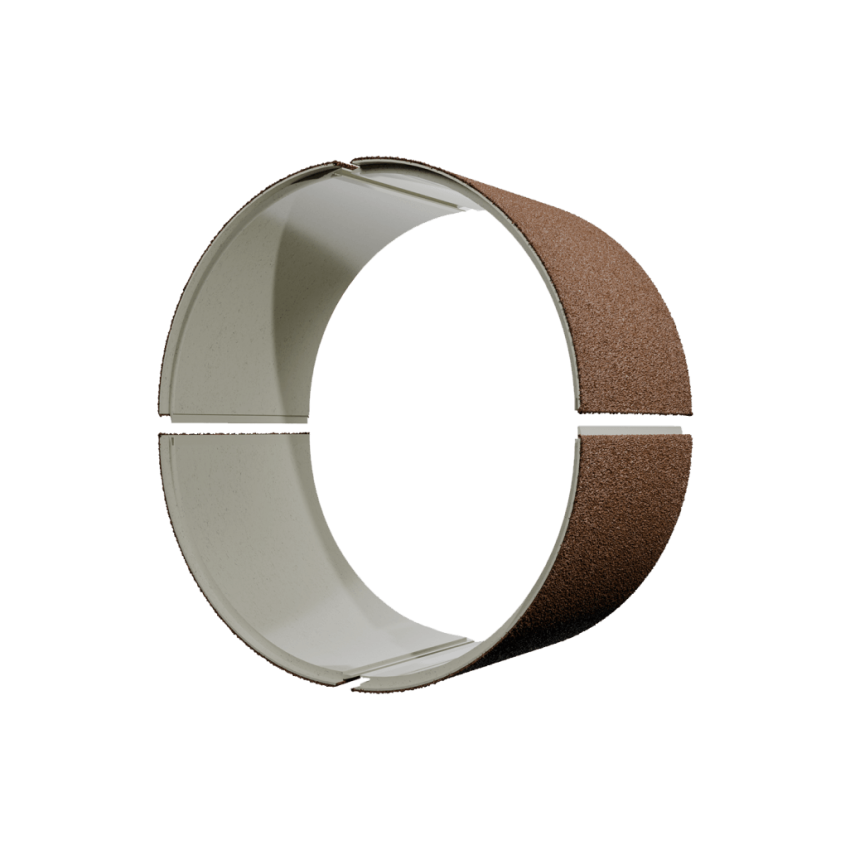

Our completely bespoke design and manufacturing capabilities mean we can provide fully-structural liner products at any shape, and any size. We also offer multi-segmental products that are perfect for large-diameter projects or more complex logistical needs.

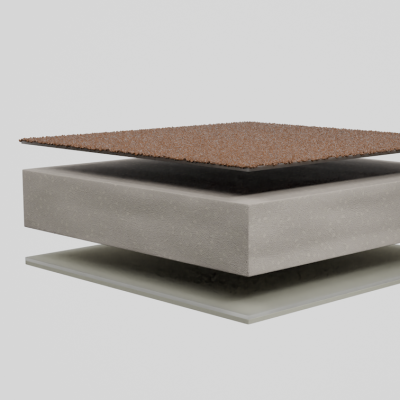

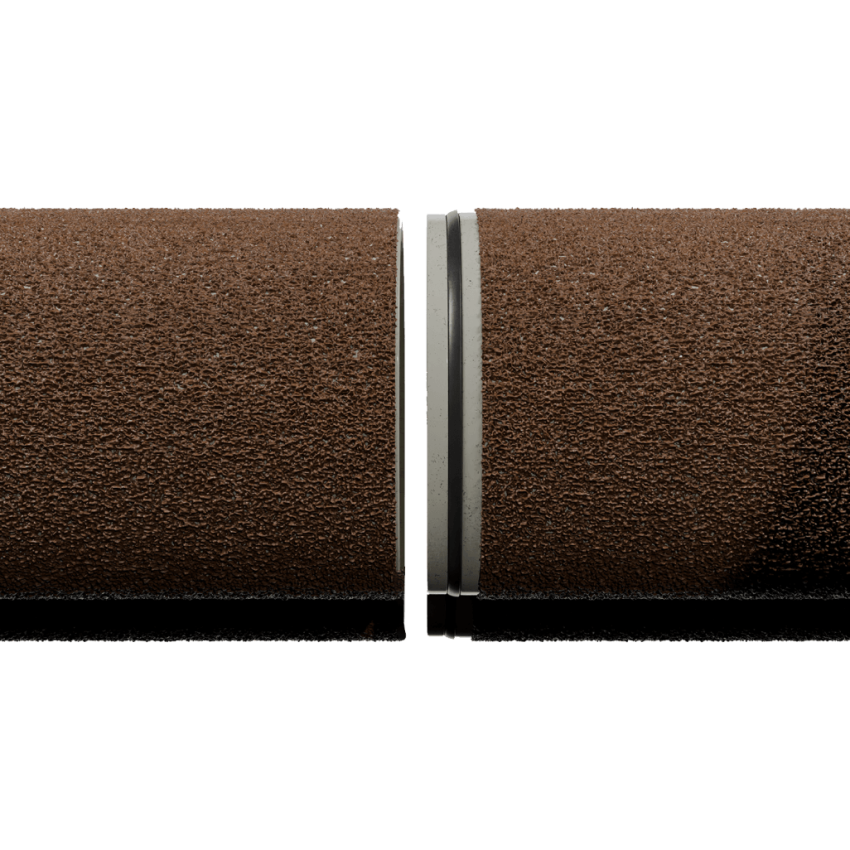

Thinner than standard GRP

Our patented technology uses a sandwich panel method combining a unique polymer and aggregate core. This means that our product is remarkably stiff and strong, but with a relatively thin wall. This is important as we maintain as much cross-sectional area as possible.

How we work

Project evaluation

Our expert team take care to understand the requirements and nuances of each project. This usually involves surveying the host pipe, which we can help arrange, and a site visit.

Bespoke design service

Our in-house design team creates a custom design to fully satisfy project requirements and specifications. If required, the design can be validated using finite element analysis.

Manufacture, with quality in mind

The bespoke manufacture of product begins. Quality control is undertaken both during and on completion of the manufacturing process. If required, third party inspection and validation can be arranged.

Dedicated logistics support

The finished solution is prepared for shipping and dispatched to the project location. Our dedicated logistics team and client liaison provide end-to-end support until the arrival of goods.

Installation supervision

Training and support for installation can be provided by our team on request.

Industries

Applications

01

Wastewater

Buried, large-diameter pipelines and culverts have represented the backbone of any city’s utility network, in some cases for hundreds of years, but many of these are failing due to age. Channeline's fully-structural rehabilitation solutions give a new life to existing structures.

02

Stormwater

Heavy rainfall and impervious surfaces such as roofs and asphalt roads leading rain directly into sewer systems often cause sewers and wastewater treatment plants to reach their full capacity. An effective and reliable network of stormwater drainage infrastructure is needed to combat this challenge. Channeline offers a fully-structural rehabilitation solution for stormwater drainage systems.

03

Rail and road culverts

Culvert design has to consider a number of factors like the weight of the surrounding soil and roads, the soil type of the foundations, and the expected water properties including their flow rates. Channeline products are custom designed and manufactured, meaning we can take all of these factors into consideration, producing a fully-structural solution that effectively rehabilitates each unique culvert.

04

Seawater cooling networks

Usually seawater cooling systems use steel pipes and replacement is very expensive. Channeline offers a cost-effective alternative to replacement, instead rehabilitating the existing structure using our fully-structural liners.

05

Tunnels

Channeline’s capability to manufacture large-diameter, multi-segmental products enables the fully-structural rehabilitation of tunnels of any size.

06

Custom

Channeline excels in crafting bespoke solutions tailored to meet diverse client needs. Leveraging cutting-edge technology and extensive expertise, we meticulously design and manufacture custom products for various applications.