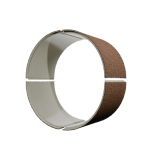

Standard liner

Infrastructure rehabilitation is a critical task for maintaining the functionality and safety of urban environments. From aging sewer systems to deteriorating stormwater pipes, repairs are inevitable. However, traditional methods often come with significant challenges: road closures, lengthy construction times, environmental impact, and public frustration. Enter trenchless technology —a modern solution that not only addresses these issues but revolutionizes how infrastructure repairs are done.

What is trenchless technology?

Trenchless technology is a type of subsurface construction work that minimizes or eliminates the need for extensive trenching. It uses methods and materials capable of installation beneath the surface of the ground.

Some popular trenchless methods are:

-

Horizontal Directional Drilling (HDD): A guided, surface-based drilling rig creates an underground borehole, then pulls the pipe, cable, or other line through the drilled hole.

-

Microtunneling: Launched from a pit, this method is used to create straight-line tunnels, this method is suitable for projects requiring large-diameter tunnels, such as those for trains or pedestrians.

-

Direct Pipe: This technique combines excavation of the borehole and pipeline installation into a single process.

Trenchless rehabilitation uses this technology to repair, rehabilitate, or replace existing buried pipes and structures without, or with minimal, excavation.

The problem with traditional methods

Traditional infrastructure rehabilitation involves open trenching, where large sections of land are excavated to access damaged pipes. While effective, this approach comes with significant downsides:

-

Traffic disruption: Major road closures can lead to traffic jams, delays, and frustration for commuters. Businesses located along construction zones can suffer reduced foot traffic and revenue loss.

-

Noise and air pollution: Excavation machinery and heavy vehicles create a noisy, dusty environment that impacts residents and nearby businesses.

-

Extended timelines: Traditional methods often take weeks or months to complete, causing prolonged inconvenience to the public.

-

Environmental impact: Open trenching disturbs soil and vegetation, potentially leading to erosion, habitat destruction, and water pollution.

These challenges make trenchless installation a more attractive option for modern cities.

Benefits of trenchless installation

1. Reduced surface disruption

Trenchless installation requires minimal digging. Small entry and exit points are created for accessing underground structures, leaving the surface largely untouched. This means:

-

Roads stay open for traffic

-

Businesses and residents experience fewer interruptions

-

Urban landscapes remain intact

2. Faster completion times

Without the need to excavate, repair, and restore large areas, trenchless methods significantly reduce project timelines. In some cases, what would take weeks with traditional methods can be completed in days. This rapid execution minimizes inconvenience for the public.

3. Cost savings

Trenchless installation eliminates the need for:

-

Extensive excavation and backfilling

-

Surface restoration (e.g., repaving roads, replanting grass)

-

Traffic control measures over prolonged periods

Municipalities and businesses benefit from lower project costs and fewer financial losses due to disruptions.

4. Environmental advantages

Trenchless methods are more eco-friendly compared to traditional open trenching. Benefits include:

-

Reduced carbon emissions from machinery

-

Minimal impact on surrounding vegetation and ecosystems

-

Lower risk of contaminating water sources

For cities committed to sustainability, trenchless installation aligns with green initiatives.

5. Adaptability to urban environments

In densely populated areas where space is limited, trenchless installation excels. It can navigate around existing utilities, buildings, and other structures, making it ideal for cities with complex underground networks.

How our bespoke GRP liners take trenchless to the next level

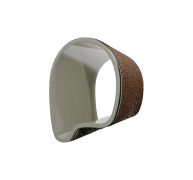

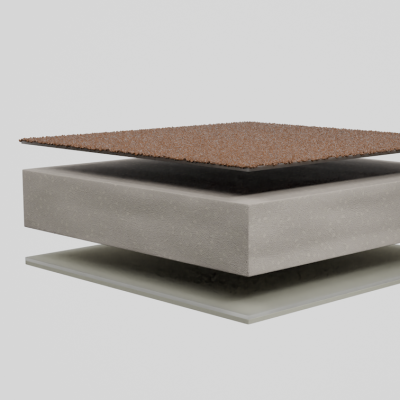

Channeline specialize in manufacturing fully-structural GRP (glass reinforced plastic) liners that can be customized to fit any shape or size. This flexibility is crucial for rehabilitating irregularly shaped structures like culverts, tunnels, and unique pipe configurations. Combined with trenchless installation methods, our GRP liners offer:

-

Performance: perfect fits for all structures, which in turn enhances performance included increasing hydraulic capacity

-

Durability: GRP liners resist corrosion and wear, extending the lifespan of rehabilitated infrastructure

-

Multi-segmental options: our unique multi-segmental technology gives more trenchless installation options so you can complete even the hardest job with minimal disruption