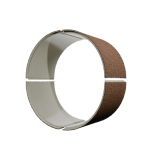

Standard liner

When it comes to rehabilitating critical infrastructure like wastewater pipes, stormwater drains, and culverts, glass reinforced plastic (GRP) liners are increasingly the solution of choice. However, despite their proven success, there are still several misconceptions surrounding GRP liners that can lead to hesitation or misinformed decisions.

At Channeline, we’ve been pioneers in GRP lining technology for decades, so we want to set the record straight on GRP liners by revealing the reality behind the five most common myths.

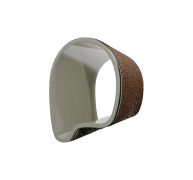

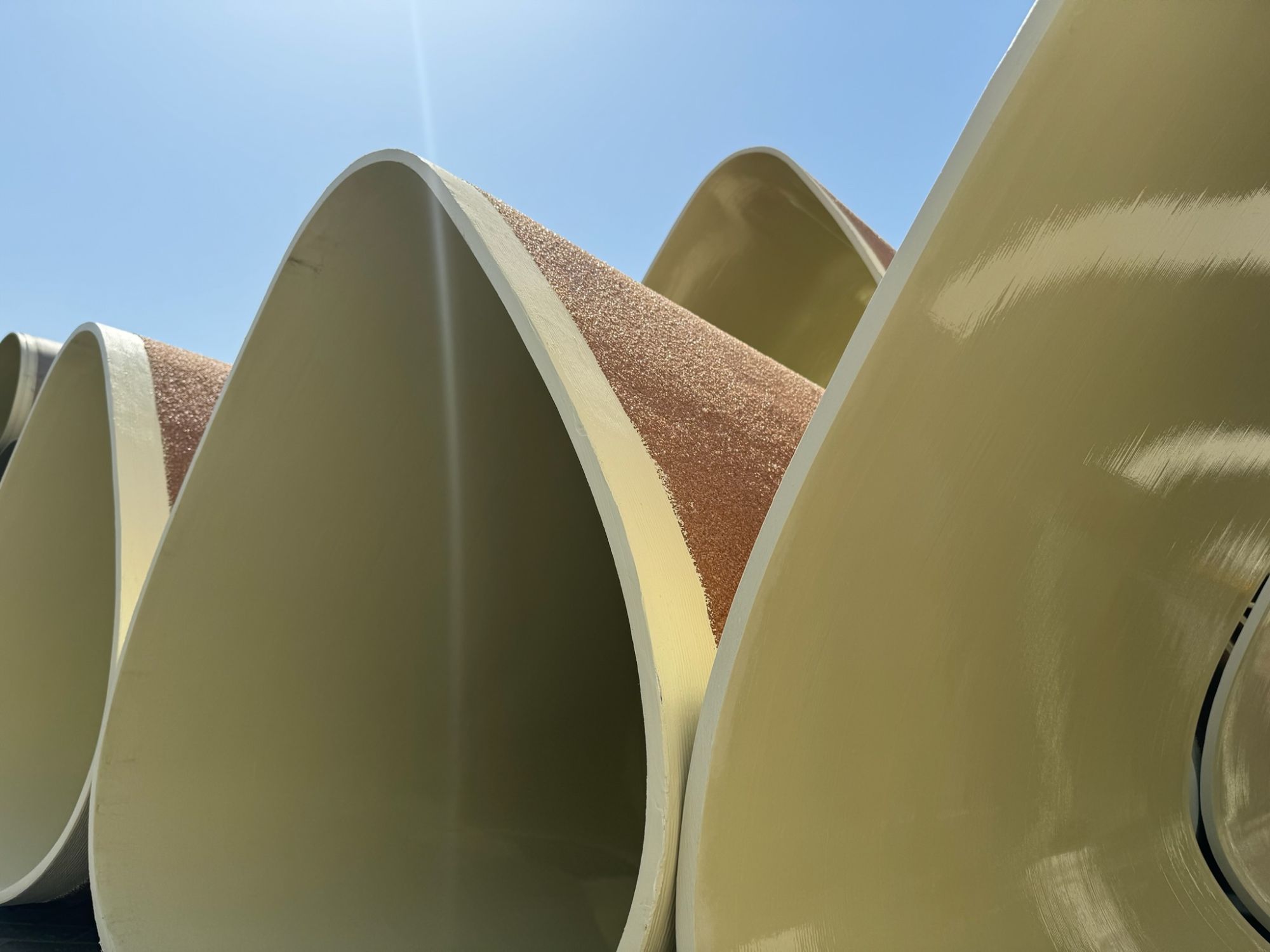

Myth 1: GRP liners are only suitable for circular profiles and standard diameters

Reality:

One of the most persistent misconceptions about GRP liners is that they’re limited to circular profiles and off-the-shelf sizes. In fact, Channeline’s GRP liners are completely custom designed and manufactured to precisely match any shape and size of host structure. Our unique multi-segmental liners even allow us to rehabilitate infrastructure with spans exceeding several meters.

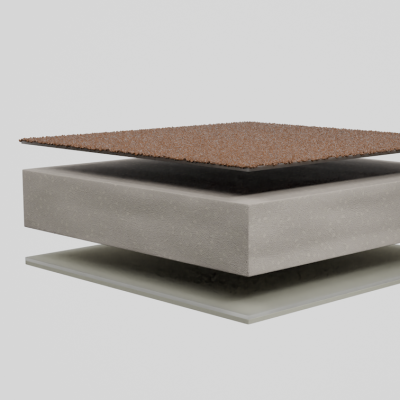

Myth 2: GRP liners are fragile compared to other materials

Reality:

This couldn’t be further from the truth. GRP liners are engineered for strength and durability, offering exceptional resistance to physical loads, chemical attack, and corrosion. Their high strength-to-weight ratio allows them to outperform many traditional rehabilitation materials, especially in environments prone to aggressive flows, chemical exposure, or extreme weather conditions.

In fact, Channeline liners are a fully-structural rehabilitation solution, meaning that they are strong enough to bear 100% of all specified loads without relying on the host structure’s residual strength.

Myth 3: GRP liners are too expensive

Reality:

While the initial cost of GRP liners might seem higher than some alternative materials, the long-term cost savings are undeniable. GRP liners dramatically reduce maintenance requirements, offer decades of reliable service, and minimize the risk of catastrophic failures that can lead to expensive emergency repairs.

When you factor in the extended service life, reduced downtime, and lower installation costs (due to trenchless techniques), GRP liners deliver a superior return on investment compared to traditional methods.

Myth 4: Installing GRP liners requires major excavation

Reality:

One of the greatest advantages of GRP liners is that they enable trenchless rehabilitation, drastically reducing the need for excavation. Installation typically involves minimal surface disruption, preserving surrounding infrastructure, reducing traffic interruptions, and saving significant project costs.

This makes GRP lining especially valuable for projects in urban areas, under railways, or beneath heavily trafficked roads where traditional dig-and-replace methods would be highly disruptive.

Myth 5: GRP liners aren’t a sustainable solution

Reality:

Sustainability is a growing priority across all industries, and GRP liners are more environmentally responsible than many assume. Unlike traditional materials like concrete and steel, GRP requires significantly less energy to produce — up to 75% less than steel — and generates fewer emissions.

Channeline’s GRP liners are also designed to last 150 years, reducing the need for frequent repairs and material consumption. Their lightweight design lowers transportation emissions, and the use of abundant raw materials like sand makes GRP a smarter, more sustainable long-term choice for infrastructure rehabilitation.

Final thoughts

GRP liners have revolutionized infrastructure rehabilitation — offering strength, durability, sustainability, and cost-effectiveness in a single solution.

At Channeline, we’re committed to helping asset owners, engineers, and contractors make informed decisions based on facts, not myths. If you're considering a rehabilitation project, contact us today to learn how our advanced GRP lining solutions can protect your infrastructure for generations to come.