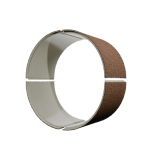

Standard liner

When rehabilitating aging or damaged infrastructure, one of the most advanced solutions available today is the use of fully-structural glass reinforced plastic (GRP) liners. But what exactly does ‘fully-structural’ mean in this context, and why is it important?

A fully-structural liner is designed to bear 100% of all specified loads (including internal pressures, external soil and traffic loads, and other environmental stresses) without relying on the host structure’s residual strength. It functions as a stand-alone structure inside the original host structure, capable of maintaining integrity even if the host fails completely. This sets it apart from semi-structural or non-structural liners, which rely on the condition of the original structure for support and performance.

How do fully-structural GRP liners work?

Fully-structural GRP liners, like those manufactured by Channeline, are constructed from strong, corrosion-resistant materials. Each liner is designed with precise wall thickness and structural strength to meet both short-term and long-term stress requirements, independent of the host structure.

The typical installation process involves inserting pre-manufactured liner sections into the host and securing them in place. Once installed, the liner becomes the new pipe, capable of withstanding loads, flow, and environmental exposure without relying on the host’s structural capacity.

Fully-structural at scale

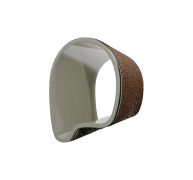

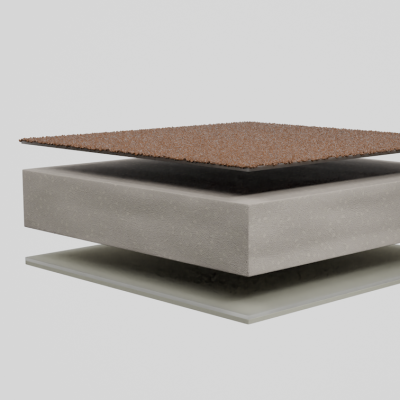

While most Channeline liners arrive fully-structural from the factory, very large diameters may require multi-segmental liners, which are assembled on-site. These are bonded together using Channelbond, a high-performance adhesive engineered specifically by Channeline for this application. Channelbond is resistant to 14 different chemicals, ensuring that joints remain watertight, chemically stable, and structurally sound over time. This innovative system allows for the creation of fully-structural liners at virtually any scale, making it ideal for large or complex rehabilitation projects.

Longevity and durability

A major advantage of fully-structural GRP liners is their exceptional lifespan. Channeline’s liners have a design life of 150 years, meaning they are engineered to perform as intended for at least that duration—even under challenging conditions.

This long service life is made possible by:

-

High-quality composite materials

-

Precision-engineered strength and wall thickness

-

Resistance to corrosion, abrasion, and a wide range of chemicals

-

Reliable structural performance even if the host pipe fully deteriorates

The result is a future-proof rehabilitation solution with minimal maintenance requirements and maximum confidence.

Conclusion

Fully-structural GRP liners represent the gold standard in infrastructure rehabilitation. With the ability to completely replace the structural function of failing pipes, these liners offer a reliable, long-term solution for aging infrastructure.

Channeline’s fully-structural GRP liners combine customizability, chemical resistance, and a 150-year design life with the industry’s most advanced installation technologies. Whether for standard profiles or large-diameter, multi-segmental projects, these liners deliver a level of strength and resilience that ensures infrastructure integrity for generations to come.