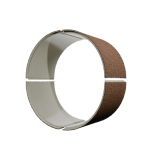

Standard liner

As a manufacturer of bespoke GRP liners since the early 1980s, Channeline have made liners of all shapes and sizes. Specializing in large-diameter liners, we noticed a problem: how can we transport extremely large liners?

Our solution: muti-segmental liner technology.

What is a multi-segmental liner?

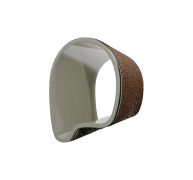

A multi-segmental liner is simply a GRP liner made up of two or more pieces. Channeline’s innovative multi-segmental liners use patented tongue-and-groove technology. This allows even complex geometries to be divided into multiple segments while maintaining structural integrity and load capacity.

Dividing liners into multiple segments makes transportation easier, not only for liners so large that they would not otherwise fit into standard shipping containers but also for greater efficiency. Mutli-segemental liner pieces can be shipped in a ‘nested’ formation, meaning that many more liners can fit into a single container. For example, if a single-piece requires five trucks, a multi-segmental may only require one or two for the same length of liner. This reduces both shipping costs and carbon emissions. Not only that, nesting multi-segmental liners into standard sized containers means that there is no need for road closures, escorts or other factors common with larger shipping loads that negatively impact the communities around the project location.

The role of Channelbond

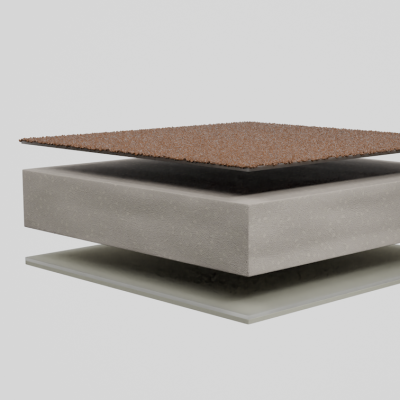

A critical factor in maintaining the strength of multi-segmental liners is Channelbond, a specially-engineered structural adhesive. Resistant to 14 different chemicals, Channelbond ensures that bonded segments maintain full integrity, offering a service life of 150 years; comparable to that of Channeline’s single-piece liners.

No compromise on strength

While breaking large liners into smaller segments clearly improves transportability, the key question remains: can a multi-segmental liner truly match or even exceed the strength of a single-piece liner? The answer is a resounding yes.

Our innovative jointing system has been designed so that the load carrying capacity of joints is actually increased, not decreased. That is, it takes more load to deflect a multi-segmental liner than a single-piece liner. This has been tested using the ring stiffness test and the apparent hoop tensile strength test. The multi-segmental liners have also undergone long-term strain corrosion testing, where load is applied to the sample, which is also put under environmental factors under deflected condition, and the time to failure is recorded. This means that rather than being a weak point, the joints actually enhance the overall structural performance.

Conclusion

Channeline’s multi-segmental liner technology addressed a fundamental challenge in large-diameter rehabilitation projects: transportation. More importantly, thorough testing has proven that this does not come at the compromise of strength or durability. In fact, the unique joints actually enhance structural performance, making this approach both practical and effective for large-scale infrastructure projects.