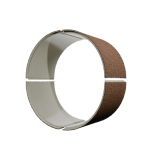

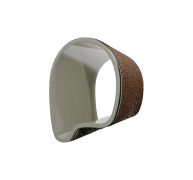

Standard liner

In the infrastructure rehabilitation industry, the combination of innovative solutions and skilled execution is essential for success. Advanced trenchless technologies and materials like GRP (glass reinforced plastic) have revolutionized how we approach aging infrastructure, but their effectiveness hinges on education and training.

From manufacturers to contractors, training is a vital part of ensuring that pipeline rehabilitation projects are executed efficiently, safely, and to the highest standards.

Why training matters

Pipeline rehabilitation is a highly technical process that requires precision engineering, industry collaboration, and detailed execution.

Technical knowledge

Comprehensive technical training ensures consistent, high-quality results in critical areas such as:

-

Manufacturing and quality control: Ensuring products meet the highest standards before they leave the factory.

-

Assembly techniques: To guarantee seamless installation.

-

Inspection protocols: The skills and knowledge to verify installations meet specifications.

-

Maintenance and repair procedures: Equipping teams to extend product lifespan or repair issues.

Minimizing risk

Rehabilitation projects often face tight timelines and challenging environments. Training helps mitigate risks by:

-

Teaching workers to adhere to safety protocols.

-

Demonstrating best practices to avoid costly errors.

-

Preparing teams to handle troubleshooting during installations.

When teams are well-trained, projects are completed faster, more safely, and with fewer setbacks, creating value for contractors, clients, and end users alike.

Education at Channeline

At Channeline, we believe that exceptional solutions require exceptional training. Since the 1980s, we’ve been a global leader in bespoke structural GRP lining systems, trusted for their adaptability and durability. However, we understand that even the best products need expert installation to deliver maximum value. That’s why we prioritize training for both our internal team and external partners.

Training our team: a foundation of excellence

Quality begins within. We provide extensive training to our team to ensure that every step of the production process meets rigorous standards. This includes:

-

Design standards: Keeping our design teams up-to-date with the latest international guidelines to ensure compliance.

-

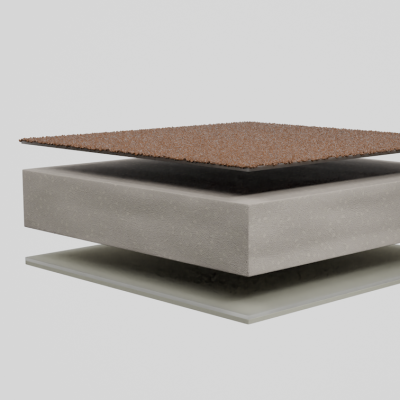

Manufacturing techniques: Perfecting our processes to deliver durable, reliable liners.

-

Inspection and QA/QC methods: Maintaining quality at every stage of production.

This internal expertise forms the foundation of every successful project we deliver.

On-site training: supporting contractors and clients

Our dedication to education extends beyond our staff to the contractors and clients who use our products. We provide tailored on-site training and support to ensure that installation is efficient and effective.

-

Custom training: We create site-specific training programs that address the unique requirements of each project.

-

Mock installations: Supervised practice sessions provide contractors with hands-on experience, building confidence and preparing them for real-world execution.

This commitment to on-site education fosters trust and collaboration between Channeline and our clients, ensuring project success.

Driving innovation through education

Education plays a pivotal role in driving innovation within the rehabilitation industry. As the industry is constantly evolving, with new technologies and materials entering the market, investing in training and education ensures that professionals are up-to-date, empowered and confident to integrate innovative solutions effectively.

It also fosters a culture of problem-solving and adaptability, enabling teams to tackle unique challenges with creative solutions. By investing in education, the pipeline rehabilitation industry can unlock new possibilities, improve project outcomes, and build a sustainable future.