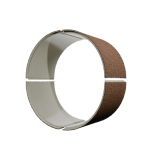

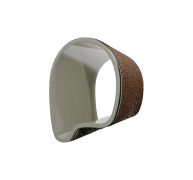

Standard liner

Sustainability has become a critical priority in almost every industry, and none more so than construction. According to Composites UK, the construction industry consumes more resources taken from the earth (up to 50%) than any other industry. As we confront the growing environmental challenges of climate change, resource depletion, and pollution, it is imperative that industries, including construction, reduce their impact on the environment to ensure a sustainable future.

The importance of sustainable infrastructure solutions

Infrastructure forms the backbone of modern society, supporting everything from transportation and water management to energy distribution and waste treatment. However, the environmental toll of building and maintaining this infrastructure is immense. Traditional materials like steel, concrete, and aluminum are resource-intensive to produce, transport, and install, leading to significant carbon emissions and resource depletion. Additionally, these materials often have relatively short service lives, requiring frequent maintenance and replacement, further contributing to waste and energy consumption.

As we look to the future, it’s clear that sustainability must be at the heart of our infrastructure solutions. This means not only reducing the environmental impact of material production but also extending the lifespan of the materials we use. By making smart material choices, we can drastically reduce the environmental footprint of infrastructure projects while ensuring the longevity and resilience of our built environment.

Why GRP is the sustainable choice

Glass reinforced plastic (GRP) stands out as a key solution for sustainable infrastructure, offering numerous environmental and performance advantages over traditional materials like concrete and steel. Here’s why:

-

Longevity and durability

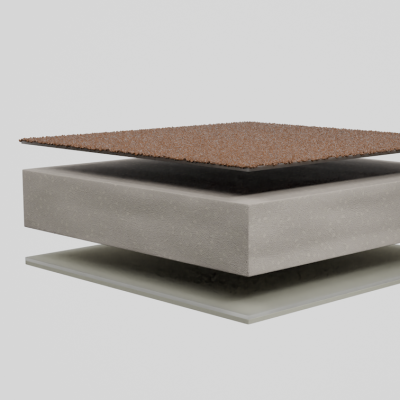

One of the most compelling reasons why GRP is a sustainable choice is its exceptional longevity. GRP is highly resistant to extreme temperatures, UV radiation, and chemical exposure, making it ideal for use in harsh environments. With minimal maintenance required over its lifetime, GRP can last for decades—often outlasting the very materials it replaces. Channeline’s GRP products, for instance, have a service life of 150 years. This extended lifespan significantly reduces the need for frequent replacements, cutting down on resource consumption, waste, and the environmental burden associated with ongoing infrastructure maintenance. -

Energy efficiency and carbon footprint reduction

GRP’s lightweight nature offers substantial environmental benefits, especially when it comes to transportation and installation. Because GRP is much lighter than materials like steel and concrete, less energy is required to transport it to construction sites. This leads to reduced emissions from transportation vehicles and fewer shipments overall, improving air quality and minimizing environmental harm. At Channeline, our GRP liners can be designed in shorter lengths that can be transported efficiently. Additionally, our multi-segmental liners can be nested during transport, reducing the number of shipping containers required. These logistical efficiencies further lower the carbon footprint of each project, making GRP a more environmentally friendly choice. -

Lower energy consumption in production

The production of GRP is significantly more energy-efficient compared to other common infrastructure materials. It requires 75% less energy to produce GRP than steel, and it generates fewer greenhouse gasses during manufacture. GRP’s production process also consumes less energy than that of both steel and aluminum, making it a more sustainable option from the very start. -

Abundant and sustainable raw materials

GRP is made using glass fibers, which are derived from sand—an abundant and widely available natural resource. Unlike other materials whose raw components may become depleted over time, sand is not expected to be exhausted. Additionally, the resin used in GRP production is derived from a by-product of refined crude oil, ensuring that this material makes use of existing resources rather than contributing to new extraction efforts.

The clear path forward

As the world continues to grapple with the pressing need for sustainable infrastructure, materials like glass reinforced plastic (GRP) offer a clear path forward. GRP’s long lifespan, reduced energy consumption, and reliance on abundant raw materials make it a sustainable alternative to traditional materials such as concrete and steel. By choosing GRP, we can significantly lower the environmental impact of construction projects while ensuring that our infrastructure lasts longer, requires less maintenance, and contributes to a healthier planet.

At Channeline, we envisage a future where the world's infrastructure thrives sustainably, ensuring the safety and prosperity of generations to come. Through our innovative design and technologies, we are helping to build a more sustainable future, one infrastructure project at a time.